Product Description

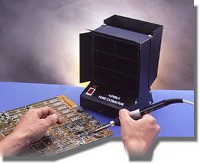

Fume Extractor

Enquiry Print Download

Features :

Flux is an integral part of the soldering process to prepare the work surface. Composed of rosin-resin and mixed with an activator (halogen organic agent) that, as the temperature increases, generate noxious components such as salicylic acid and pinene commonly seen as smoke rising from the work area. High content ratios of resin generate phinol (C6H5OH) and the activators can emit hydrogen chloride (HCL) and other compounds. The US Government has occupational hazard standards controlling the permissible amounts of such compounds in the work area and the SOLMAX 456 and FUME EXTRACTOR 426 when used properly, help to meet these standards.

Both SOLMAX 456 & Fume Extractor 426 offer a convenient and space saving method of removing noxious fumes from the work environment. Designed for use on the factory floor, in R&D or by the hobbyist, these new products provide an economical and efficient method to improve the work place by eliminating headaches, nausea and eye irritations often associated with exposure to solder fumes.

Both 456 and 426 were developed with a high performance fan and an easy to replace activated carbon filter.The filter is made by joining specific foam with refined activated carbon. The activated carbon has a surface area of 1250 m square/gram and the total weight of the filter is 500 grams/meter square. The dust collection efficiency of the filter is 30% while the carbon filter can absorb up to 30% of its carbon weight in noxious components.

Soldering Iron ( 456DLX Only )

Electronic Temperature Controlled, Continuously Adjustable.

Highly Insulated Ceramic Heater.

Zero Voltage Switching (Spike Free).

Fast Heat Up And Instant Heat Recovery.

Fume Extractor (426DLX Only)

Built In High Efficiency, Low Noise, Brushless Mini Fan.

Easy To Replace Activated Carbon Filter Effec tively Absorbs Noxious Flux And Lead Fumes.

Quickly Removes Smoke And Fumes.